On the jewelry side, Patrick recognized the need for a better material for body jewelry, one that would be safe for the body and prevent damage to teeth caused by metals.

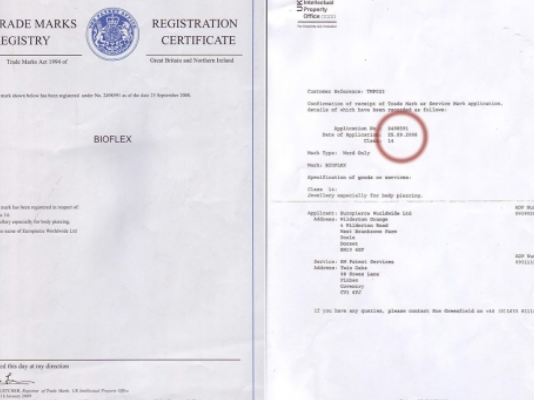

After 2 years of research and development, this led him to develop the BioFlex , a flexible, highly certified medical grade plastic material that is now widely used in industry.

Building on the success of BioFlex, Patrick created Europierce Worldwide Ltd to develop a wide range of body jewelry BioFlex ® .

In addition to registering with the Sheffield Assay Office in the United Kingdom with its own initials “PP”, In 2001, he also created his own range of high-end body jewelry.

Gold jewelry 18 carats , in platinum, in titanium medical grade And surgical steel with real diamonds And semi-precious stones have been custom made for customers.

He believes we should all wear the right size of body jewelry to limit any skin irritation and migration of piercings while optimizing people's comfort.

He created his own specific tools for applying high precision micro-wires for body jewelry in gold, silver, titanium and surgical steel.

As piercings are not always accepted everywhere in our society, Patrick found solutions to resolve disputes between employees and companies, and between schools and students because pierced people from all backgrounds wanted to keep both their jobs and their piercings.

Range “Hide it” of BioFlex ® has been successfully created to appeal to both parties with nose, lip and ear cartilage retainers, once again helping the piercing industry!

Patrick a été contacté par des studios de cinéma pour développer des pièces spécifiques en titane pour le fameux film Wallace & Gromit par example.

The jeweled banana safe and flexible in BioFlex® was created and was a success in the largest UK retail chain “ARGOS” .

The belly bar has been designed to allow to pregnant women to keep their piercing safe throughout their pregnancy because the flexibility of the BioFlex® accompanied the growth of the belly.

Patrick worked with passion to develop the range of his " baby " BioFlex ® and this led him to receive calls and visits from the largest body jewelry distributors around the world who put BioFlex® in their catalogs, bringing more people to know about it.

Knowing well that glue contains cyanide, it was impossible to glue jewelry to any material to be used in body jewelry.

We then set up our proprietary thermal process to set crystals in plastic without using glue, which is safer on the body and has become an industry standard for hygiene .

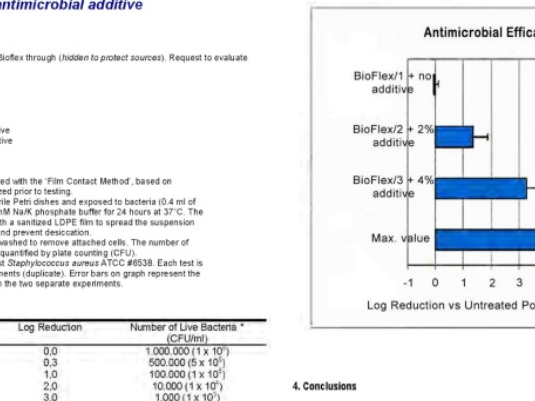

With the creation of the new company Jewelry BioFlex EURL in France he continued to innovate and introduced body jewelry antimicrobials based on Silver Ion technology well before any pandemic.

This was developed with the help of the laboratory at the University of Dijon in France using the material BioFlex ® which has been carefully tested and approved.

Based on the latest advances in micropore technology, the range BioFlex ® Fragrance was born with the help of the greatest perfumers in the industry.

This allowed bad odors from skin wearing jewelry to disappear and once again, a gesture was made for the comfort and hygiene of those with piercings.

Patrick a été contacté par Yves Handrich , un scientifique du CNRS de renommée mondiale of the' IRPC (Institut pluridisciplinaire Hubert Curien) pour l’aider à fabriquer des pièces BioFlex spécifiques pour percer les manchots dans le cadre d’une étude sur le suivi de leurs migrations a l aide de « GPS Trackers ».

L »idée n’était pas seulement d’aider la science, mais les pingouins eux-mêmes; BioFlex ® helped reduce temperature transfer underwater.

Its flexibility added comfort when wearing the GPS tracker fixed on the back and avoided the use of metals being a material on and medical grade.

Patrick's concern for security led him to create the “push-fit system” which is intended to " to separate " the two parts of the body jewelry under the effect of a shock .

This innovation prevents damage to the skin in the event of an accident, making it a significant breakthrough in the industry.

Amidst the madness with all the multiple sizes of jewelry available on the market, we created the system “Multi-use tube”.

He allows people to use threaded jewelry external , with thread internal and to fit on a single piece which can be cut to any length !

This solved many problems at once for the consumer.

Today, Patrick founded Poli International Co Ltd , which is dedicated to the improvement and innovation of tattoo and piercing products .

Producer notably For the disposable market while taking into account of its environmental issues, we are using recyclable plastics while developing bio-friendly materials.

The idea of a multi-use tube system inspired a well-established American company to create an innovative toy to help children build anything they can think of by creating the range of themed puzzle games » Wacky Links » .

This range won 12 prices from different institutions and was presented on Fox News as one of the top seven recommendations to add to a stocking stuffer.

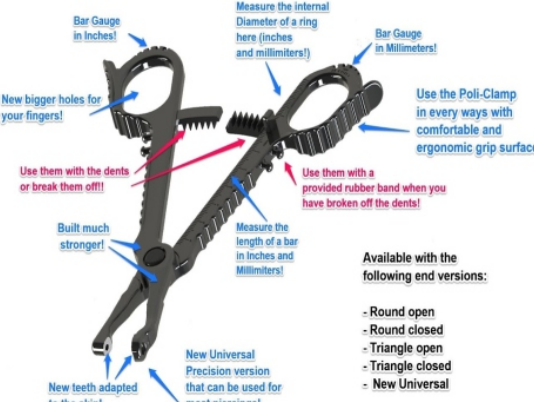

Patrick designed the “Poli Clamp” in 2017 using his many years of experience in piercing.

Innovate by creating a breaking point on the pliers teeth allowing piercers to easily break it to use a rubber band or retain plastic teeth to hold the skin for the piercing process.

Also adding better ergonomics to allow comfort not only for the piercer but also for the client, and a suite of measurement guides on the pliers to help the piercer check jewelry diameters, lengths and gauges before drilling.

We introduced the first silicone body parts “tattooable” and the first tattooable silicone ear plugs, as well as a wide range of innovative tattooable silicone body jewelry displays.

By changing habits of using metal to hold body jewelry on displays, we created our own design of “anti-scratch clips” to avoid scratching jewelry which represents a dirt trap for bacteria, thus adding another step for better hygiene.

A range of grip jetables stérilisées innovantes et confortables for tattoo machine manufacturers was created in two versions.

One with high resilience foam to fit most brands of machines, and another version in Bi-material with an advanced thermoplastic elastomer (TPE) for additional comfort added to an ergonomic design.

Patrick created with his son Frédéric a new range of RCA and specific cables for tattoo machines taking into account the problems tattooists face daily with poor connections and cable hardness.

The innovation here lies in the cable connectors bi-material, injected on weld for “fix” the contacts with a hard material, overmolded with a safe advanced thermoplastic elastomer.

This offers softness, comfort and a flexible cable specially designed to accompany the tattooist's movements.

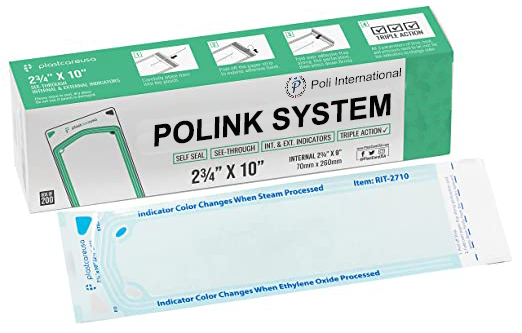

THE “POLINK System” is not only a revolutionary ink delivery system that simplifies the tattooing process and provides benefits to the tattoo community, it is the long-awaited achievement that has brought 2 years to develop !

Compatible with most types of cartridge needles, established tattoo machine brands and all brands of tattoo ink, this is a universal system which saves time, reduces disruption when tattooing and reduces ink and plastic waste, making it eco-friendly.

The POLINK system is a major innovation which provides comfort, efficiency and reliability to tattoo artists and suppliers, helping to evolve the tattoo industry.

The “POLINK system” is not only

a revolutionary ink delivery system

which simplifies the process of

tattoo and offers benefits to

the tattoo community is

long-awaited achievement

which took 2 years to develop!

Compatible with most types of cartridge needles, tattoo machine brands

established and all tattoo ink brands, this is a universal system which saves time, reduces disturbances during tattooing and reduce ink and plastic waste, which makes it environmentally friendly.

The POLINK system is a major innovation

which offers comfort,

efficiency and reliability

tattoo artists and suppliers, contributing to

to evolve the tattoo industry.